The medical device industry is undergoing a period of rapid transformation. Driven by advancements in technology, increasing patient demands, and a heightened focus on efficiency and cost-effectiveness, manufacturers are constantly seeking ways to improve the performance, reliability, and lifespan of their equipment. A key area of focus is the optimization of motor performance, particularly through the integration and intelligent utilization of Variable Frequency Drives (VFDs). This trend is gaining significant momentum, fuelled by factors ranging from stringent regulatory requirements to the growing importance of sustainable practices – all amplified by the current global emphasis on resource management and energy conservation.

For decades, motors have been the workhorses of medical devices – powering everything from infusion pumps and ventilators to imaging systems and laboratory equipment. Traditional motor control methods, involving fixed-speed operation, are often inefficient and lack the precision required for many modern medical applications. This is where VFDs shine.

VFDs allow for precise control over the speed of AC motors, offering significant advantages:

The medical device industry is subject to rigorous regulatory oversight by bodies like the FDA (in the US) and the EMA (in Europe). These regulations increasingly emphasize energy efficiency and environmental sustainability. Manufacturers are under pressure to demonstrate that their devices meet strict energy performance standards.

Furthermore, rising costs of energy and raw materials are driving the need for operational efficiency. Optimizing motor performance through VFDs directly contributes to cost reduction by minimizing energy consumption. Implementing VFDs can translate into substantial savings over the lifespan of a medical device, justifying the initial investment. A study by the US Department of Energy found that VFDs can reduce energy consumption in industrial applications by 20-50%. These savings are directly applicable to the medical device sector.

The integration of Artificial Intelligence (AI) is further revolutionizing VFD performance optimization in medical devices. AI-powered systems can analyze real-time data from VFDs, including motor current, voltage, temperature, and vibration, to predict potential failures and optimize operating parameters.

Predictive maintenance, enabled by AI, minimizes downtime and prevents costly repairs. By identifying anomalies and predicting equipment needs, hospitals and medical facilities can proactively address potential issues before they impact patient care. This approach aligns perfectly with the current trend of using data analytics to enhance operational reliability, particularly in essential sectors like healthcare.

MES-Drive is at the forefront of this revolution, developing VFDs equipped with advanced AI algorithms. Their solutions provide real-time monitoring, performance analysis, and predictive maintenance capabilities, enabling medical device manufacturers to achieve unparalleled levels of efficiency and reliability.

One-size-fits-all solutions are no longer sufficient in the medical device industry. Each device has unique requirements, and VFDs need to be customized to meet those specific needs. Factors such as motor type, application requirements, and regulatory standards need to be carefully considered when selecting and configuring VFDs.

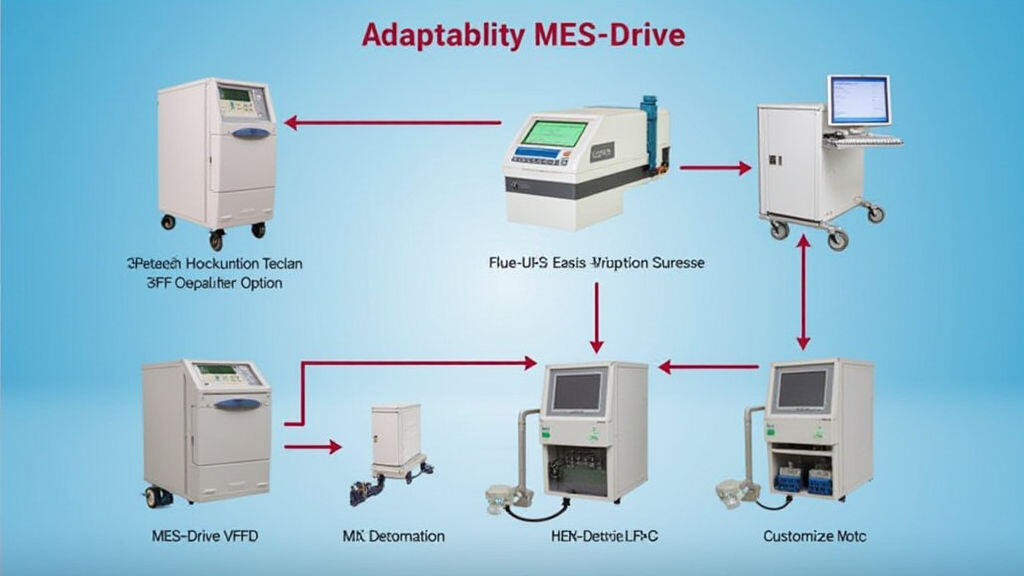

MES-Drive works closely with manufacturers to develop customized VFD solutions that are tailored to their specific devices. This includes offering a range of VFD models with different features and functionalities, as well as providing expert engineering support to ensure optimal performance.

The growing focus on sustainability is driving manufacturers to adopt more environmentally friendly practices. VFDs contribute to sustainability by reducing energy consumption, minimizing carbon emissions, and extending the lifespan of equipment.

Furthermore, VFDs can facilitate the implementation of circular economy principles. By optimizing motor performance and reducing wear and tear, VFDs help extend the lifespan of medical devices, reducing the need for frequent replacements. This minimizes electronic waste and promotes resource conservation.

The future of VFDs in medical equipment lies in connectivity and cloud integration. Connecting VFDs to the cloud enables remote monitoring, data analysis, and software updates. This provides manufacturers with valuable insights into equipment performance and allows them to proactively address potential issues.

Cloud-based platforms also facilitate collaboration between manufacturers, service providers, and end-users, fostering a more efficient and responsive ecosystem. The Internet of Medical Things (IoMT) is accelerating this trend, enabling seamless data exchange and improved decision-making.

The increasing focus on Variable Frequency Drive motor performance optimization in the medical device industry is not merely a trend; it’s a fundamental shift driven by regulatory pressures, cost considerations, and a growing commitment to sustainability. The integration of AI and cloud technologies is unlocking even greater potential for performance enhancement, predictive maintenance, and remote monitoring. As the medical device industry continues to innovate, VFDs will play an increasingly vital role in enabling the development of more efficient, reliable, and sustainable medical solutions. MES-Drive, as a leading provider of advanced VFD solutions, is well-positioned to support this evolution, empowering manufacturers to deliver cutting-edge medical devices that meet the demands of a rapidly changing world. This trend directly aligns with the current global focus on resource management and building a more sustainable future, making the optimization of VFD performance a strategically important area for medical device manufacturers to invest in.

Leave A Reply

Your email address will not be published. Required fiels are marked